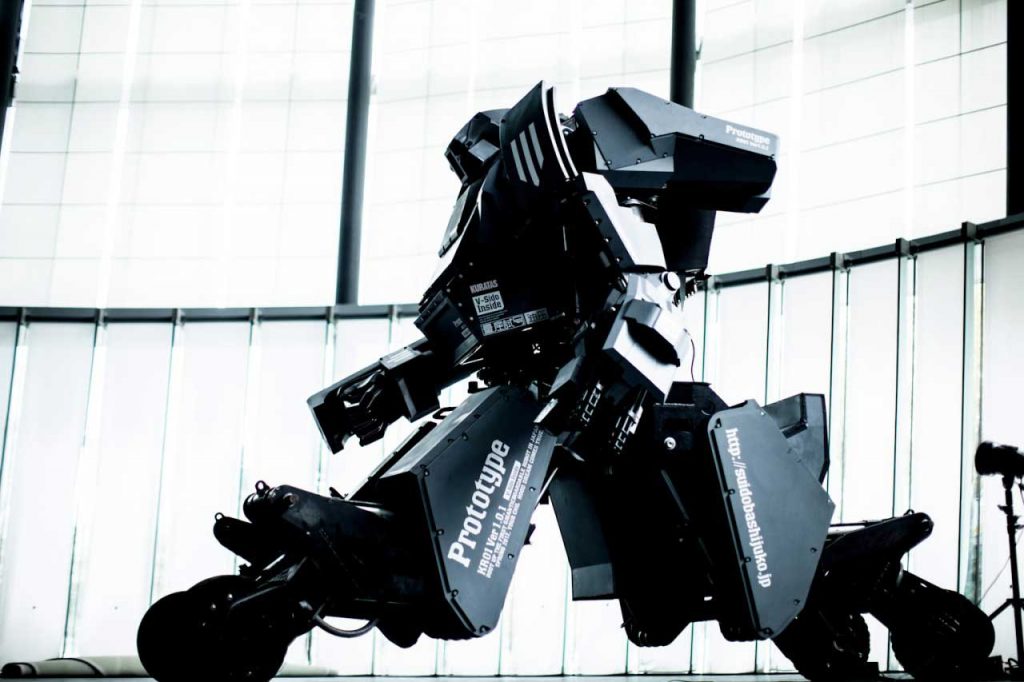

“When I was a kid, I thought there were going to be giant robots in the future. But no matter how long I waited, people were only able to make small robots, like Asimo. Eventually, I thought ‘I can’t wait anymore,’ and set out to make one myself.” Kogoro Kurata is the designer and blacksmith behind the gargantuan 4-ton mech standing in front of me. Named after its creator, Kuratas is the product of nearly three years of forging, hammering, and coding. The robot’s expressionless face towers over the crowd atop its 13-foot frame. I picture its diesel-powered hydraulic arms ripping apart the building’s steel girders.

Steel is Kurata’s specialty, both for his day job as a blacksmith, and for his “hobby.” Inspired by the plastic models from a 1980s anime series called Votoms, he initially got noticed for building a life-sized steel model of one of the program’s Armored Troopers. His next project was a natural extension. “I made Kuratas wondering ‘what would it be like if this thing actually moved?’”

To that end he recruited Wataru Yoshizaki, now a second-year doctoral student, whose V-Sido software powers the robot’s 30 hydraulic actuators. He’s also responsible for its multiple onboard weapons systems (like the smile-activated BB gatling gun), requisite iPhone connectivity, and a robotic hand that’s controlled with what looks like a Nintendo Power Glove. The two came to know one another online, and when Kurata learned how much of the student’s work could be applied to his own project, he extended an invitation: “How would you like to control my robot?” Less than two years later, the pair were showing off their first working prototype.

“IT’S FUNNY TO SEE THE PANICKED EMAILS COME IN FROM PEOPLE ABROAD, SAYING THEY THOUGHT IT WAS A JOKE.”

Suidobashi Heavy Industry is the name that Kurata operates under, believing that establishing a company would be the first step toward mass production. The group first gained attention back in July when it opened a website letting people order their own custom mechs, starting from the low price of $1.35 million. The team has received over 3,000 orders both in Japan and overseas, but so far all the customers have backed out before paying. “It’s funny to see the panicked emails come in from people abroad, saying they thought it was a joke,” says Kurata.

Luckily, Suidobashi isn’t expecting to turn a profit anytime soon; the blacksmith has said that only people who think profits are a waste of time are fit for his team. The man in charge also has another advantage of sorts: all of the money that has gone into Kuratas is his, so no one is beholden to the whims of financial sponsors. He explains that “it takes money to make things, and it takes money to borrow more money. My thinking was that if I paid for the whole thing myself I could get it done more cheaply.”

Building the robot took a lot of trial and error. Rather than start with engineering diagrams, Kurata’s starting point was a series of scale models. When it came time to start the build, the artist found that he didn’t know very much about electronics or hydraulics, and was forced to pick things up as he went along. Even now, all of the mech’s assembly is handled by Kurata, who slings the massive slabs of metal around his workshop single-handedly with an overhead crane he bought from Yahoo Auctions. He would like to experiment with walking mechanisms, but current space and equipment constraints make that difficult. Remedying the situation is apparently the first thing on his agenda.

Despite the military paint job and BB gatling guns, the artist insists Kuratas is a mech of peace. “The idea was a toy robot — it’s built for people to ride in and have fun with, not for the army or anything,” he says. And what better toy for a builder than a 4-ton chunk of childhood brought to life? Kurata doesn’t seem to mind that he might never sell a robot, that Suidobashi Heavy Industry could just be an expensive playground. It’s easy to understand why once you see the huge grin on the face of a 70-year-old woman as she steps out of Kuratas’s bombproof chest cavity after a spin as test pilot.

Hint: Use the ‘s’ and ‘d’ keys to navigate

On the decline of Japanese industry, Kurata says, “Japanese people are good with technology, but I hear people say that they don’t know what to make… You can’t really make much new without some kind of catalyst.”

Kurata’s first mech was a life-size steel replica of the Scope Dog armor from the Votoms anime series. “I made Kuratas wondering ‘what would it be like if this thing actually moved?'” said Kurata.

Kuratas’s 6,000 round-per-minute BB gatling gun can be set to fire when the pilot smiles. Other weapons like a water bottle cannon and the “pilebunker” are also up for sale.

Some lucky visitors were allowed to take a seat in Kuratas’s cockpit.

During Kuratas’s development “size and weight were problems.” Kurata improvised solutions with a forklift before caving in and buying an overhead crane on Yahoo Auctions.

Right now, the four-legged mech relies on wheels to get around, clocking a top speed of 6 miles per hour. Kurata would like to experiment with walking, but is constrained by his current space and equipment.

A space is cleared of Suidobashi logos to make room for the team’s sponsors.

Instead of starting with design diagrams, Kurata began with scale models. Afterward, he created a full-sized version from steel, refining it through trial and error.

Yoshizaki’s software, called V-Sido, powers the robot. Kurata found out about the student’s work through blog comments.

“Steel is my specialty, so that wasn’t a problem, but I didn’t know very much at all about electricity. Hydraulics were the same — when I needed to know something I looked it up.”

The total price of a Kuratas starts at $1.35 million, but goes up depending on your options. “From the beginning, our business model was to target oil barons,” says Kurata.

A lucky audience member gets to sit in the Kuratas’s cockpit. The robot can also be controlled externally with a master-slave function.

Kuratas relies on 30 hydraulic actuators to move its hulking body. A valve and actuator upgrade means Kuratas can move more than twice as quickly as it could in July.

When Kurata isn’t building giant mechs, he makes a living blacksmithing. “I make things for ads, things that move… steel is the basis of pretty much all of my work

via theverge.com